Restroom Sanitation Standards: Elevating Hygiene in Monterey Offices

Restrooms broadcast a facility’s commitment to health more than any other space. When occupants encounter stained fixtures or lingering odors, confidence in overall cleanliness plummets—regardless of how pristine the lobby may look. UFG Monterey recognizes that effective restroom sanitation hinges on microbiological control, material preservation, and consistent occupant experience. This article details the company’s standards‑driven program that transforms office restrooms from potential pathogen reservoirs into hygienic, odor‑free environments.

Public Health Imperative

Restrooms concentrate the highest density of moisture, organic soil, and hand contact within an office. Pathogens such as norovirus and influenza can survive for days on stainless‑steel flush handles or plastic soap levers. Cal/OSHA regulations require employers to maintain restrooms “in a sanitary condition,” but the regulation offers little tactical guidance. UFG Monterey bridges that gap through measurable protocols aligned with CDC and APIC recommendations, ensuring surfaces remain below 2.5 colony‑forming units per square centimeter on random ATP tests.

Science‑Backed Cleaning Chemistry

Disinfection efficacy derives from matching chemistry to soil type and contact time. UFG Monterey deploys a hospital‑grade quaternary ammonium disinfectant registered on EPA List Q for emerging viral pathogens. The product offers a five‑minute dwell time at 1:256 dilution, balancing microbial kill spectrum with material compatibility on chrome, porcelain, and solid‑surface counters. Citric‑acid bowl cleaners dissolve hard‑water scale caused by Monterey’s 220 ppm mineral content, while remaining low‑VOC to protect indoor air quality.

Daily Cleaning Sequence

A standardized “clean‑move‑disinfect” method guides technicians from ceiling vent to floor drain, preventing cross‑contamination and missed edges. The entire procedure unfolds in under 20 minutes for a four‑fixture restroom, keeping facilities available during peak breaks.

Essential daily steps include:

- High‑dust exhaust grilles and light lenses with treated microfiber sleeves.

- Apply descaler to urinals and bowls; allow dwell while mirrors and counters are serviced.

- Remove trash liners, inspect bins for leaks, and disinfect receptacle interiors.

- Wipe mirrors with ammonia‑free glass cleaner, followed by counter disinfection.

- Agitate and rinse toilet fixtures, disinfect flush levers, and polish chrome.

- Damp‑mop floors with neutral pH solution, starting at the far corner and finishing at the exit.

This list remains the backbone of hygiene, with deeper services layered on weekly cycles.

Odor Neutralization Strategies

Persistent odors often stem from urine that seeps under fixture bases or penetrates porous grout. UFG Monterey seals new grout lines annually with breathable, water‑based impregnators to create a barrier. Enzyme‑based digesters applied during overnight service break down uric salts that traditional disinfectants leave behind. Air‑handling checks ensure negative pressure within restrooms, preventing odor migration into corridors. The result is a space that smells neutral rather than artificially perfumed.

Consumable Management and Touch‑Free Technology

Paper and soap shortages undermine user confidence faster than visible soil. UFG Monterey maintains a cloud inventory system: each restock logs dispenser ID, refill volume, and time stamp. Data analytics flag dispensers averaging abnormal usage spikes—often an early sign of vandalism or leaks. Touch‑free faucets, flushometers, and soap dispensers foster hygiene while reducing surface recontamination. All batteries follow a preventive replacement schedule tied to manufacturer life expectancy, averting sensor downtime.

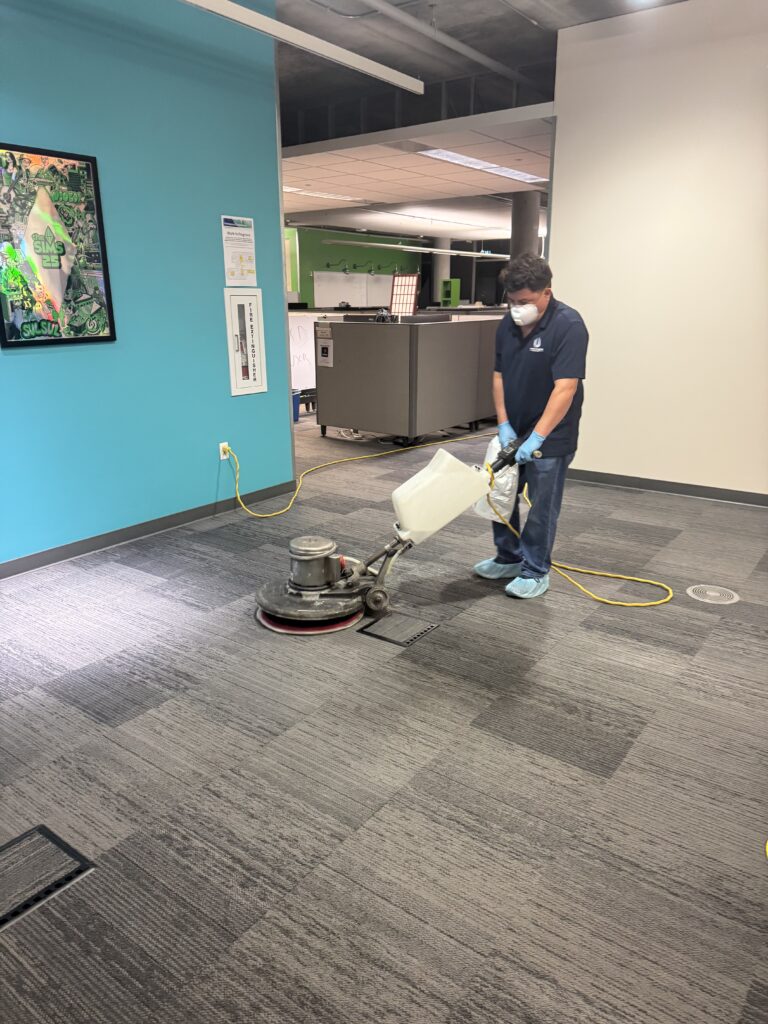

Periodic Deep‑Cleaning Tactics

Though daily tasks control routine soil, mineral accretions and biofilm accumulate over time. Monthly deep cleans include mechanical scrubbing of grout with rotary brushes and application of 12 percent hydrogen‑peroxide cleaner that lifts tannin stains without bleaching floor finish. Stainless partitions receive micro‑abrasive cream to remove fingerprint etching, restoring uniform sheen. Exhaust fans are disabled briefly to fog the room with an electrostatic sprayer charged with hypochlorous acid, coating stall undersides that manual wiping cannot reach.

Training and Safety

Technicians are the frontline defense against restroom‑borne illness. UFG Monterey requires a dedicated eight‑hour “Restroom Sanitation Specialist” module: chemical hazard labels, sequence rehearsal, PPE donning and doffing, and ATP swab practice. Slip hazards decrease through color‑coded floor warning cones and microfiber flat mop heads with 300 gram absorbency, leaving surfaces dry within six minutes. Supervisors perform surprise audits, verifying that goggles, nitrile gloves, and chemical splash aprons remain in use throughout descaling stages.

Measurement and Continuous Improvement

Visual inspection alone cannot validate microbiological safety. Weekly ATP readings at toilet flush levers, stall latches, and faucet pins feed into a dashboard; failure to remain below threshold triggers root‑cause review and immediate retraining. Additional metrics measure:

- Mean odor complaints per 1,000 occupants per month.

- Fixture‑downtime hours linked to cleaning activity.

- Water consumption per restroom after aerator installation.

Trend analysis informs chemical adjustments, equipment upgrades, and schedule shifts to match occupancy patterns.

Sustainability Considerations

Restroom services contribute significantly to a facility’s environmental footprint. UFG Monterey selects Green Seal‑certified tissue with 100 percent recycled content and installs controlled‑use dispensers that reduce sheet consumption by 25 percent. Concentrated cleaning chemicals in 2‑liter closed‑loop cartridges slash plastic waste by 80 percent versus ready‑to‑use quart bottles. Smart faucets drop flow to 0.35 gallons per minute, saving an average of 6,000 gallons annually in a 100‑person office.

Restroom sanitation is equal parts microbiology, process discipline, and user perception. Through evidence‑based chemistry, technology‑enabled monitoring, and rigorously trained staff, UFG Monterey elevates hygiene far above minimum compliance. The outcome is a restroom experience that consistently reinforces health, safety, and the organization’s commitment to excellence.